Greater motor field control

- Built in field controller as standard

- Gives excellent field control for the majority of DC motors

- Reduces the need for external components

Enhanced field control with FXMP25

- The FXMP25 may be controlled digitally by using a standard RJ45 connection, allowing set-up by standard drive parameters

- The FXMP25 can also function in standalone mode using its integrated keypad and display

Enhanced system design

- The heatsink cooling fans are intelligently controlled and only run when required, thus increasing reliability and reducing maintenance

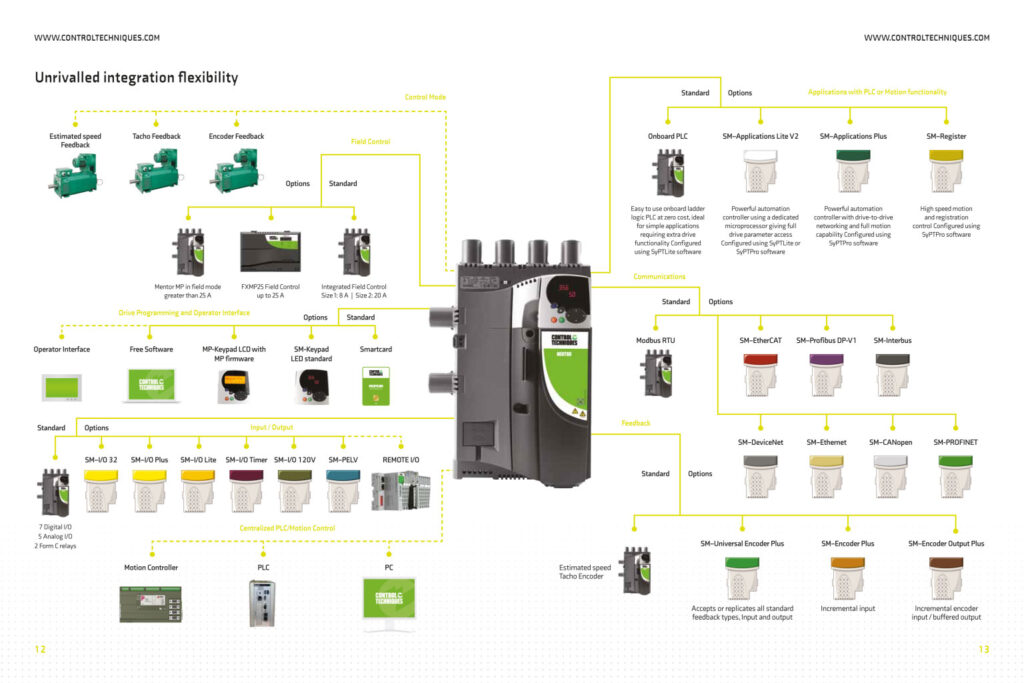

- Eighteen different option modules allow customisation of the drive, including fieldbus, Ethernet, I/O, extra feedback devices and motion controllers

- The drive system designer is able to embed automation and motion control within the drive, eliminating communications delays that reduce performance

Fast set-up, configuration and monitoring

- Quick and easy to set-up

- Can be configured using optional removable keypads

- Advanced autotune features help you get the best performance from your machine

- PC software and Smartcard tools for rapid commissioning

- Intelligent networked system with CTNet

- Program inbuilt controller with SyPTLite

- Develop tailored solutions for applications modules with SyPTPro

- Option modules for all common Industrial Ethernet, fieldbus networks

Retro-fit projects

- Easy integration with your existing motor, power supply, application equipment and communication networks has been ensured from the design stage

- Mentor MP brings performance and possibilities to your application with minimum migration costs

Ease of migration

- Mentor MP has been designed so existing Mentor II customers can easily migrate to the new platform

- All power terminal locations and mounting points have been retained

- Mentor MP has a much smaller frame size than the 900 A Mentor II with paralleling options to offer high power density

- CT Soft has a built in migration wizard to assist with the transfer of drive parameters and programs

- Smaller cable requirements make connections within the cubical easier. Construction of a custom-made bus-bar is not required

Motor Field Control

- Built in field controller as standard in every Mentor MP

- Gives excellent field control for the majority of DC motors

- Reduces the need for external components

An external motor field controller is recommended when:

-

- The required field current is greater than that offered by the standard drive, up to 25 A. For example, older motors with low field voltages

- The field is required to be forced down more quickly than is possible with a standard half controlled field bridge

- Applications can be implemented with simple field current reversal, without armature reversal, if machine dynamics can still be met